Unconventional testing machines development and realization

Our team has more than 20 years of experience in the field of research, development, production of testing machines, development of modern unconventional testing methods, metallographic specimen preparations, testing materials, automatization of industrial processes and enviromental technologies, calibration of measuring devices and development of control software and hardware.

For our constructions we use the newest hi-tech materials, sensors, machinery parts, developer software and machining technologies.

Our strengths

Products

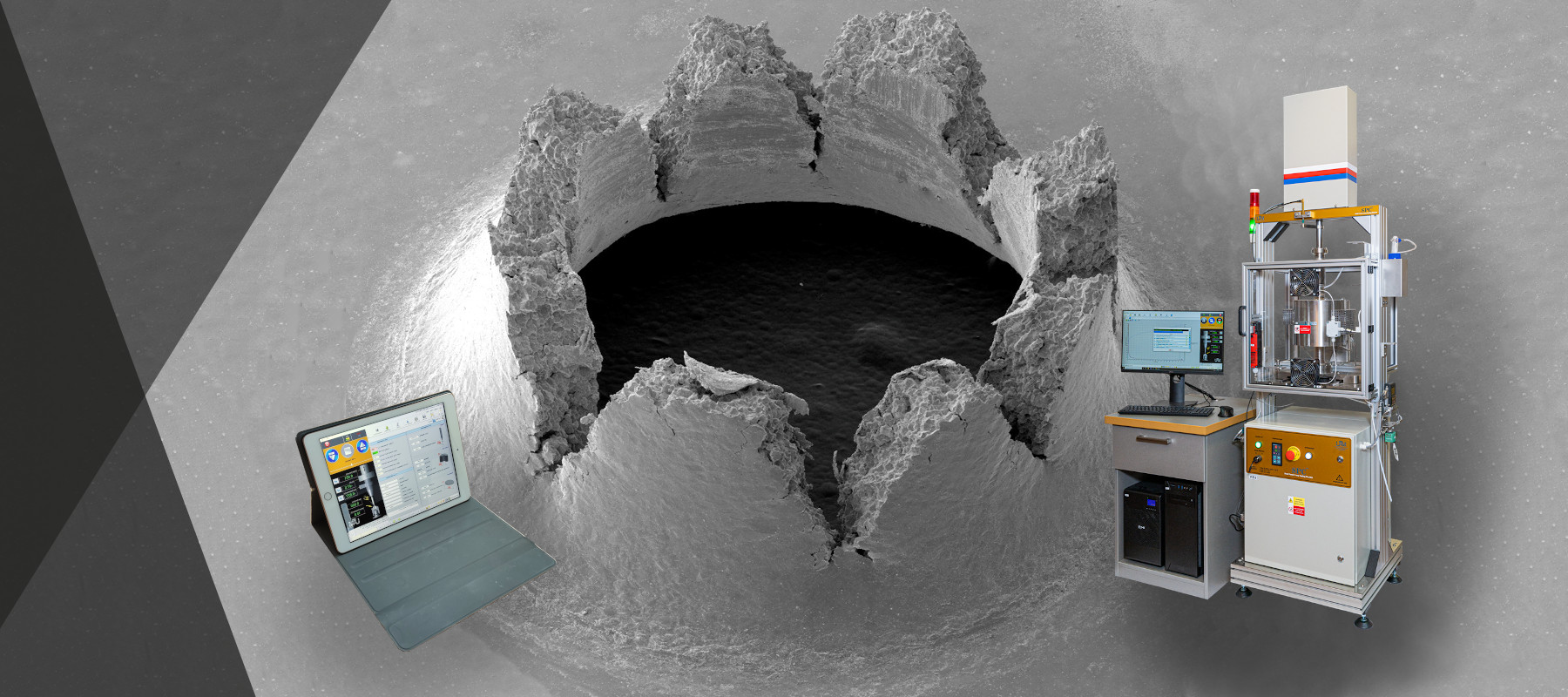

SCOOPER 50

Scoop sampling machine

Fully automatic, portable equipment for in-situ material extraction from structural components without their affecting, virtually without notch. Extracted material of hemispherical shape can be used for chemical, metalographic or electronmicroscopic analyses, for determination of mechanical material properties (e.g. by Small Punch Test, Small Punch Creep Test, Impression Creep Test etc.)

SPC 800

Small Punch Creep Testing machine for material testing in accordance with EN 10371 with loading arm

Semi-automatic testing machine for residual life estimation of structural components operating at elevated temperatures using Small Punch Creep Test method in accordance with EN 10371. Specimen is protected by argon, load is applied by the arm, maximum testing temperature 800°C, load 500N.

SPC 800/1000 DLS

Small Punch Creep Testing Machine for material testing in accordance with EN 10371 with direct load system

Fully automatic testing machine for residual life estimation of structural components operating at elevated temperatures using Small Punch Creep Test method in accordance with EN 10371.

TTS 190

Small Punch Test system for tensile and fracture material properties determination in accordance with EN 10371

Highly sophisticated testing system for mechanical material properties determination (YS, UTS, FATT) using Small Punch Test method in accordance with EN 10371.

PIIS 3000

Non-destructive, portable Instrumented Indentation Tester

Fully automatic, non-destructive, portable instrumented indentation testing machine designed for determining mechanical material properties (yield strength, ultimate tensile strength, strain hardening exponent, strain hardening exponent constant, Young's modulus, accumulated yield strain, Brinell hardness), fracture toughness (critical SIF for mode I KIC, II KIC), weld residual stress, of structural components operating under industrial conditions (in-situ) using instrumented indentation testing method (IIT) in accordance with B0950, B0951, ISO/TR 29381, KEPIC code MDF A370 and ASME Code case 2703.

GE 76

Tool for specimen manufacturing intended for Small Punch Test or Small Punch Creep Test method

High precise tool for manufacturing specimens (Ø8mm, thickness 0,5±0,005 mm) in for steps according to EN 10371 “Metallic materials – Small punch test method”) intended for Small Punch Test or Small Punch Creep Test method.

PT 8

Tool for cutting out the circular shape of the sample intended for the Small Punch Test or Small Punch Creep Test

The tool is intended for cutting a circular sample (Ø 8 mm) from sheet material with a thickness of up to 0.8 mm. The sample must be further reground to the final dimension according to the requirements of the European test standard EN 10371 “Metallic materials - Small punch test method”

Services

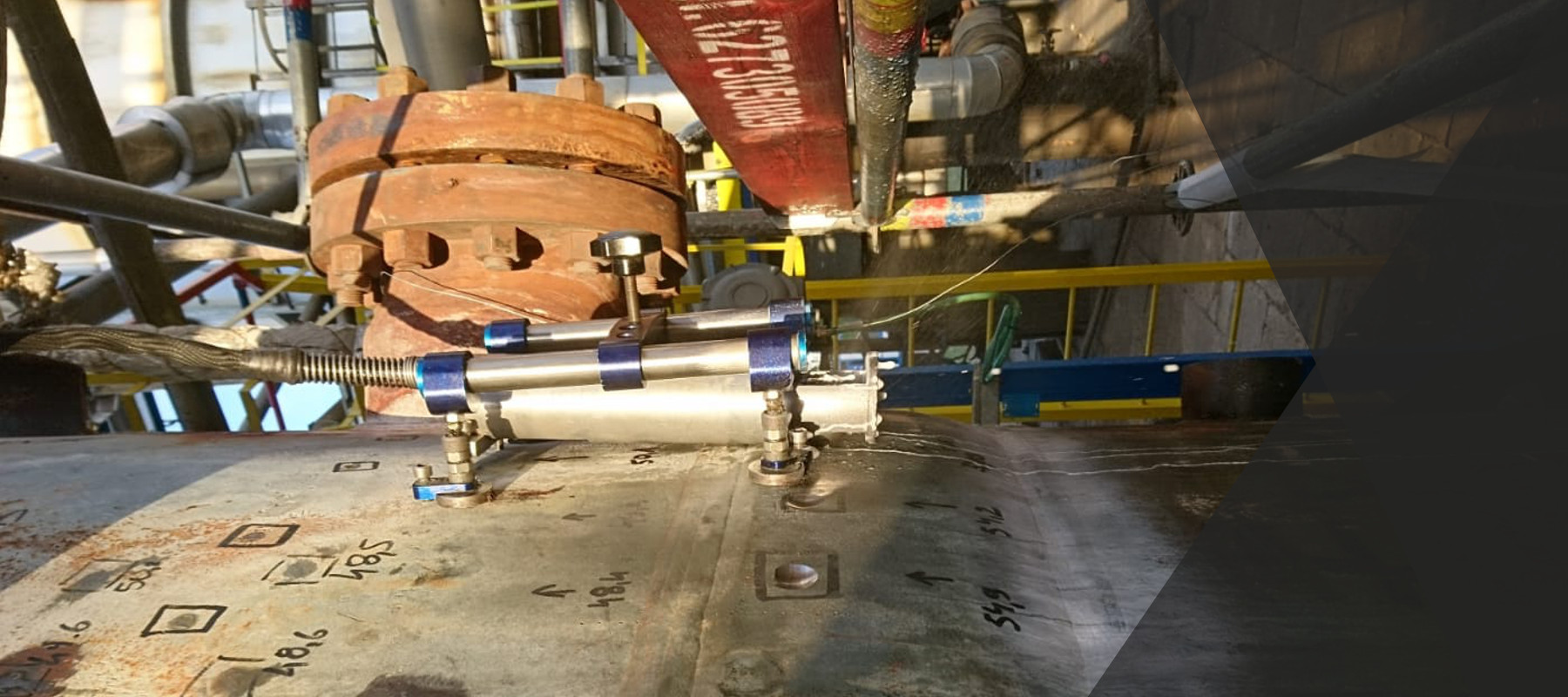

Scoop sampling

Do you need a specimen for your analysis and you do not have a scoop sampling machine?

No problem, our experienced team is ready to help you…

Small punch specimens manufacturing

Do you have a material and you need to manufacture small punch specimens with accuracy according to EN10371?

Just send it to us and our laboratory technicians will do it quickly, accurately and reliably.

News

Proposal of EN 10371 was approved

In December 2020 was approved a proposal of new standard EN 10371 „Metallic materials. Small punch test method“ and will be published as EN standard. According to CEN (European Committee for Standardization), the final text will be ready on 11 March 2020 and publication of the final standard is foreseen on 11 June 2021. Results of voting are here.

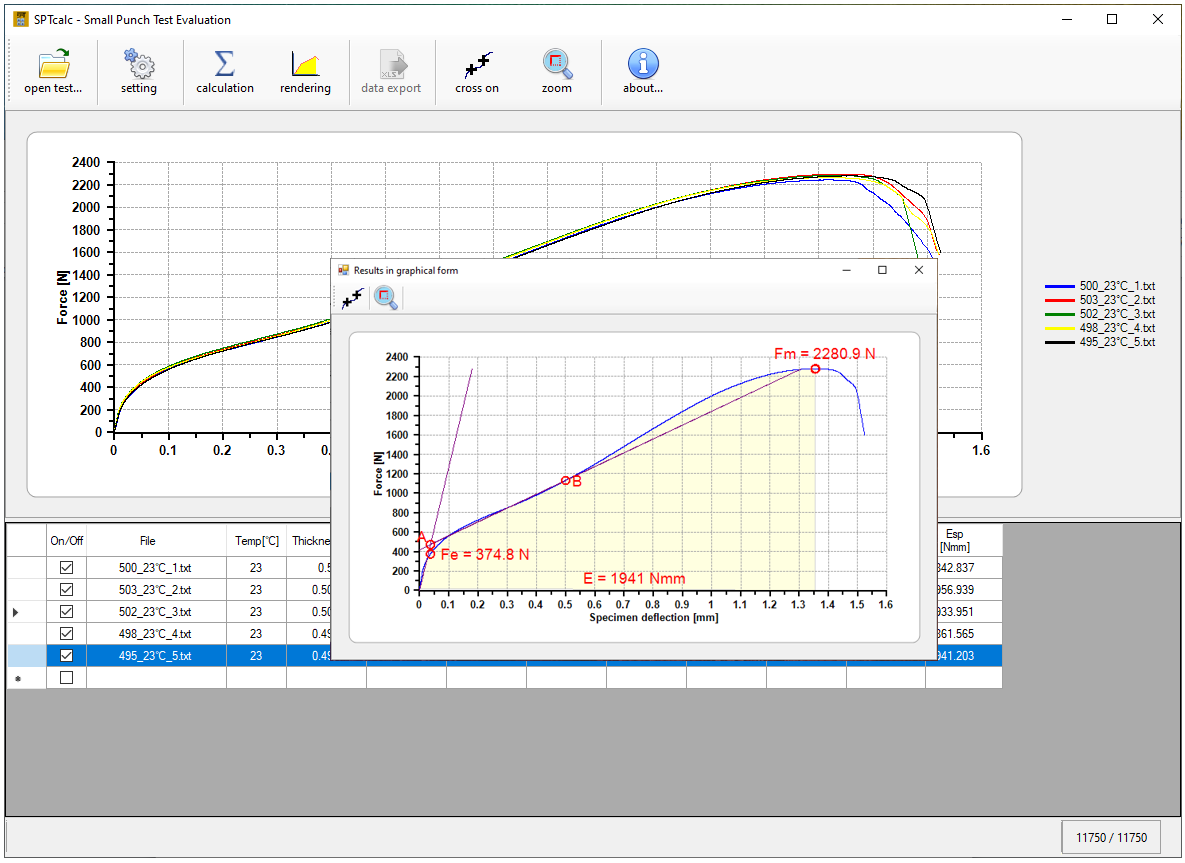

New version of SPTcalc™ – software for Small Punch Test results evaluation

New version of software for evaluation measured test data from Small Punch Tests was finished and tested. Results are evaluated in accordance with proposal of European standard EN 10371 „Metallic materials. Small punch test method“.

Main features:

- Data import from files *.dat, *.csv, *.txt (specimen deflection, punch displacement, crossbeam displacement)

- Fe point determination by bilinear method

- Yield stress Re calculation based on EN 10371 annex C,D equation C.1, C.2

- Automatic Fm determination

- Ultimate tensile strength Rm calculation based on EN 10371 annex C,D equation C.1, C.2

- Calculating energy from deflection curve or displacement curve

- Possibility of editing Fm point - method drag and drop – automatic energy recalculation

- Possibility of zero shift based on strength for measured curves

- Transferring the resulting energy to a transition temperature file

Headquarters

UTMdev s. r. o.

Vystavni 198/134

703 00 Ostrava-Vitkovice

Czech Republic

+420 608 615 303

ID: 089 99 228

VAT: CZ 089 99 228

Dealership - INDIA

Plot No 89, Door No 5/49

Vanavil Flats - A2 Natesan Nagar

Ramapuram, Chennai - 600089, India

+914 422 490 691